The effect of sampling on reproducibility increases with particle size and the width of the distribution, as the volume of sample required to ensure representative sampling of the coarse particle fraction increases.

LASER DIFFRACTION PARTICLE SIZER ISO

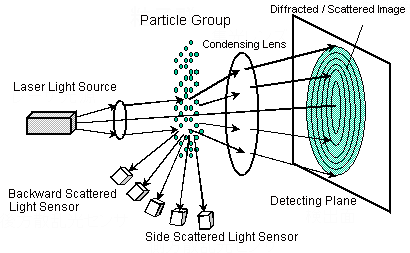

ISO 13320:2009 expressly discourages the use of specifications based on the Dv100 for this reason. This is because laser diffraction, as a volume-based technique, is extremely sensitive to small changes in the amount of coarse particles within the selected sample. Sampling issues generate the greatest errors in laser-diffraction analysis, especially when measuring large particles or when the specification is based on size parameters close to the extremes of the distribution, such as the Dv95 (the particle size below which 95% of the volume of particles exists). Obtaining a representative sample from a larger bulk is a major challenge with any kind of laboratory-based particle characterization technique. This statement neatly highlights three crucial aspects of laser-diffraction analysis: sampling, dispersion, and measurement conditions. United States Pharmacopeia ( USP) General Chapter states that laser diffraction involves the measurement of "a representative sample, dispersed at an adequate concentration in a suitable liquid or gas" (2). Method development involves addressing the wider set of practical issues that flow from this underlying explanation of the basic principles of operation. Both models assume that the measured particles are spherical, so for nonspherical samples the size distribution returned is one that is based on spherical equivalence. Furthermore, the inaccuracies that arise from the use of Fraunhofer are unpredictable. The two models return similar results for large particle sizes, but Mie offers improved accuracy for finer materials. ISO 13320:2009 provides a detailed description of both models but confirms Mie as the method of choice, especially for measurements across a wide dynamic range. The Mie theory and the Fraunhofer approximation (of Mie theory) are used routinely. With the application of an appropriate model of light behavior the particle-size distribution of the sample can be determined from the scattering data, via a deconvolution step. Using an array of detectors, laser-diffraction analyzers record the pattern of scattered light produced by the sample. Large particles generate a high scattering intensity at relatively narrow angles to the incident beam, while smaller particles produce a lower intensity signal but at much wider angles. Particles illuminated in a collimated laser-beam scatter light over a range of angles. Laser diffraction is an ensemble particle-sizing technique, which means it provides a result for the whole sample, rather than building up distributions from data for individual particles, in the way that, for example, image analysis or microscopy does. Understanding the basic principles of laser diffraction is essential for successful method development. There is a wealth of information to support method development, the success of which depends on a rigorous and systematic examination of the factors known to influence results. This process is given considerable emphasis in the International Organization for Standardization's (ISO) 13320:2009 standard for laser diffraction released at the end of 2009, reflecting that understanding of this technique among industry has grown significantly during the past decade (1).

However, streamlining measurement to this degree demands the development of a robust secure method that will consistently deliver reliable and reproducible data. As a result, for many routine users, particle-size measurement is now simply a matter of loading the sample and pressing a button.

LASER DIFFRACTION PARTICLE SIZER FULL

Fast, nondestructive and suitable for a broad size range (0.1 to 3000 μm), laser diffraction lends itself to full automation. During recent decades, the unique attributes of laser-diffraction analysis have positioned it as the particle-sizing technique of choice for the resulting spectrum of pharmaceutical applications. Particle size is a critical quality attribute for a diverse array of pharmaceutical products, from topical ointments to powders for pulmonary delivery.

0 kommentar(er)

0 kommentar(er)